TeeJet now offer two new solutions for ISOBUS sprayer control for owners of factory-installed virtual terminals, or for operators who require a complete system including a virtual terminal.

The TeeJet ISOBUS Sprayer System uses a John Deere, CASE IH or AGCO virtual terminal. The kit includes the IC18 ISOBUS Sprayer Electronic Control Unit (ECU), BoomPilot automatic boom section control module, a switch box and all cable and connection to operate on Deere, CASE IH or AGCO virtual terminals. The IC18 Sprayer ECU has an intuitive interface with advanced features such as multiple rate selection, section status and task control for prescription applications. The IC18 and BoomPilot can automatically control up to 9 sprayer sections.

The TeeJet ISOBUS Sprayer System uses a John Deere, CASE IH or AGCO virtual terminal. The kit includes the IC18 ISOBUS Sprayer Electronic Control Unit (ECU), BoomPilot automatic boom section control module, a switch box and all cable and connection to operate on Deere, CASE IH or AGCO virtual terminals. The IC18 Sprayer ECU has an intuitive interface with advanced features such as multiple rate selection, section status and task control for prescription applications. The IC18 and BoomPilot can automatically control up to 9 sprayer sections.

TeeJet Technologies also offers a sprayer control solution that includes the components noted above plus the new Matrix 570VT interface. Matrix 570VT features a bright 5.7” touch screen suitable for daylight and nighttime viewing and can be used with other ISOBUS-compatible ECUs in addition to the IC18.

TeeJet Technologies also offers a sprayer control solution that includes the components noted above plus the new Matrix 570VT interface. Matrix 570VT features a bright 5.7” touch screen suitable for daylight and nighttime viewing and can be used with other ISOBUS-compatible ECUs in addition to the IC18.

“We’re fully committed to the ISOBUS standard and want to help as many growers as possible experience the benefits of it,” said Jim Shone, Business Unit Manager at TeeJet Technologies. “Most growers don’t yet own a virtual terminal and will find our Matrix 570VT ISOBUS Sprayer System an affordable way to take full advantage of the ISOBUS platform. For the operators that do have a virtual terminal, our ISOBUS components are an economical way to leverage their current investment,” Shone continued.

TeeJet Technologies was among the first to sell ISOBUS compatible products in North America. ISOBUS job computers and controls have been in the field the last two growing seasons, and product line expansion is underway.

In 2001, farm machinery manufacturers agreed to implement a common standard for communication interfaces on tractors, implements and farm management systems. The standard is called ISO 11783 and is commonly referred to as ISOBUS.

The common standard enables products from different manufacturers to communicate and eliminates the need for separate terminals, displays and controls. Once ISOBUS is fully implemented, tractors will have a single virtual terminal in the cab.

A virtual terminal is the device that allows the operator to provide input information. An Electronic Control Unit (ECU), also known as a job computer, installed on the implement is where processing and control occurs.

Certified ISOBUS virtual terminals and ECUs will communicate and function on the same communication BUS, regardless of the manufacturer.

ISOBUS benefits:

- Operators can leverage their investment on factory installed terminals instead of having several controller consoles.

- Implements with certified ISOBUS ECUs give operators the flexibility to choose the best products for their applications without concerns about compatibility.

- Standardized plugs, cables and software simplify installation and connectivity and result in true “plug and play” technology. Operators can operate multiple implements with any tractor in their fleet.

- Data from the ECU can be easily exported and analyzed on the farm computer.

Listen to an interview with TeeJet technology specialist Jon Reinecker conducted at the National Farm Machinery Show by Agwired reporter John Davis:

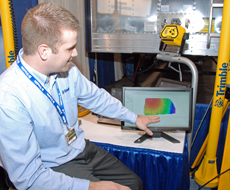

At Commodity Classic in Anaheim, CA, Jared Hayes, John Deere, was showing attendees what the company is offering to growers in the area of precision ag.

At Commodity Classic in Anaheim, CA, Jared Hayes, John Deere, was showing attendees what the company is offering to growers in the area of precision ag.

Growers stopping by the

Growers stopping by the  Precision is the name of the game when it comes to farming these days. It’s getting hard to find a farmer anymore who doesn’t use auto steer at the very least – and the options to save resources, time and money just keep growing.

Precision is the name of the game when it comes to farming these days. It’s getting hard to find a farmer anymore who doesn’t use auto steer at the very least – and the options to save resources, time and money just keep growing.  Brian Stark, who does information management for Trimble, is the company’s EZ-Sync expert. “EZ-Sync allows you to take data wirelessly from a mobile computer or from the Trimble FMX display and send that data from the field to the office,”

Brian Stark, who does information management for Trimble, is the company’s EZ-Sync expert. “EZ-Sync allows you to take data wirelessly from a mobile computer or from the Trimble FMX display and send that data from the field to the office,”  Trimble retailer Joey Schlatter of Schlatter Inc. of Francesville, Indiana

Trimble retailer Joey Schlatter of Schlatter Inc. of Francesville, Indiana

Friday, I wrote about how Ag Leader listened to customers of their SMS Advanced software and built a Certified Training program to give participants deeper knowledge that helps their own business.

Friday, I wrote about how Ag Leader listened to customers of their SMS Advanced software and built a Certified Training program to give participants deeper knowledge that helps their own business. U.S. Secretary of Agriculture Tom Vilsack gave the keynote address during the general session at the 2010 Commodity Classic in Anaheim, California on Friday and focused on the achievements of American agriculture.

U.S. Secretary of Agriculture Tom Vilsack gave the keynote address during the general session at the 2010 Commodity Classic in Anaheim, California on Friday and focused on the achievements of American agriculture. The PrecisionAg Institute can help growers know how well it Works now with a new

The PrecisionAg Institute can help growers know how well it Works now with a new