The technology of precision agriculture has long outpaced the agronomics needed to prove its investment value, but we’re a lot closer today than we were 10 years ago.

I read a recent piece by DTN agronomist Dan Davidson, written during the recent International Conference on Precision Ag in Denver, Colo. He stated, “But what is interesting is how the use of yield monitor data, grid soil sampling and variable fertilizer application hasn’t changed much in two decades with only about 20% adoption. But the introduction of lightbar navigation (80+% adoption), assisted steering and section control really showed farmers that there were benefits from adopting the right technology.”

Sure, this is oversimplification of a lot of complex factors, but we’re also dealing with a larger percentage of farmers near, at, or beyond retirement age who, most often, seek simplicity and reduced investment. One look at the light-speed adoption of glyphosate-resistant crops is one example this simplicity model. (Although that simplicity is now resulting in greater management due to resistant weeds.)

Yes, precision farming technology is complex, and turning data into sound management practices that improve the bottom line often takes hired experts, in the same vein as why crop scouts are hired. But make no mistake, the profitability of certain technologies has improved dramatically in the past 10 years. It just takes hard work by a grower to find what can pay on a given farm.

Growers wouldn’t pay $300 for a unit of seed corn if they didn’t see the value. They just have to work harder and smarter when it comes to investing in precision agriculture technology. But that process is getting easier.

Successful Farming recently compiled various statistics on how precision farming pays, based on the experience of some farmers and university experts. Check out this story from it’s special summer 2010 issue, where they highlighted such benefits as:

Successful Farming recently compiled various statistics on how precision farming pays, based on the experience of some farmers and university experts. Check out this story from it’s special summer 2010 issue, where they highlighted such benefits as:

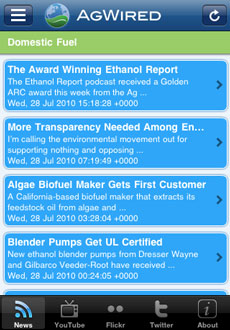

If you have an iPhone and would like to get Precision.AgWired.com posts fast and easy on it, there’s now an app for that.

If you have an iPhone and would like to get Precision.AgWired.com posts fast and easy on it, there’s now an app for that.

After a season spent trying to protect yield, we all know the view from the combine seat is judgment day for hybrids, varieties and assorted management decisions. Watching that yield monitor as you open up fields gets more focused viewership than the alma mater versus the big rival on a football Saturday.

After a season spent trying to protect yield, we all know the view from the combine seat is judgment day for hybrids, varieties and assorted management decisions. Watching that yield monitor as you open up fields gets more focused viewership than the alma mater versus the big rival on a football Saturday.