On a plane back to Denver, I was listening to the conversation taking place in the row immediately behind me. I heard a gentleman ask of his seat-mate, “Are those crop circles down there?” To which the other man responded, “No, that’s the edge of the field where the water doesn’t reach.” Also knowing the answer, I was about to chime in with: “Alex, what is center-pivot irrigation?”

On a plane back to Denver, I was listening to the conversation taking place in the row immediately behind me. I heard a gentleman ask of his seat-mate, “Are those crop circles down there?” To which the other man responded, “No, that’s the edge of the field where the water doesn’t reach.” Also knowing the answer, I was about to chime in with: “Alex, what is center-pivot irrigation?”

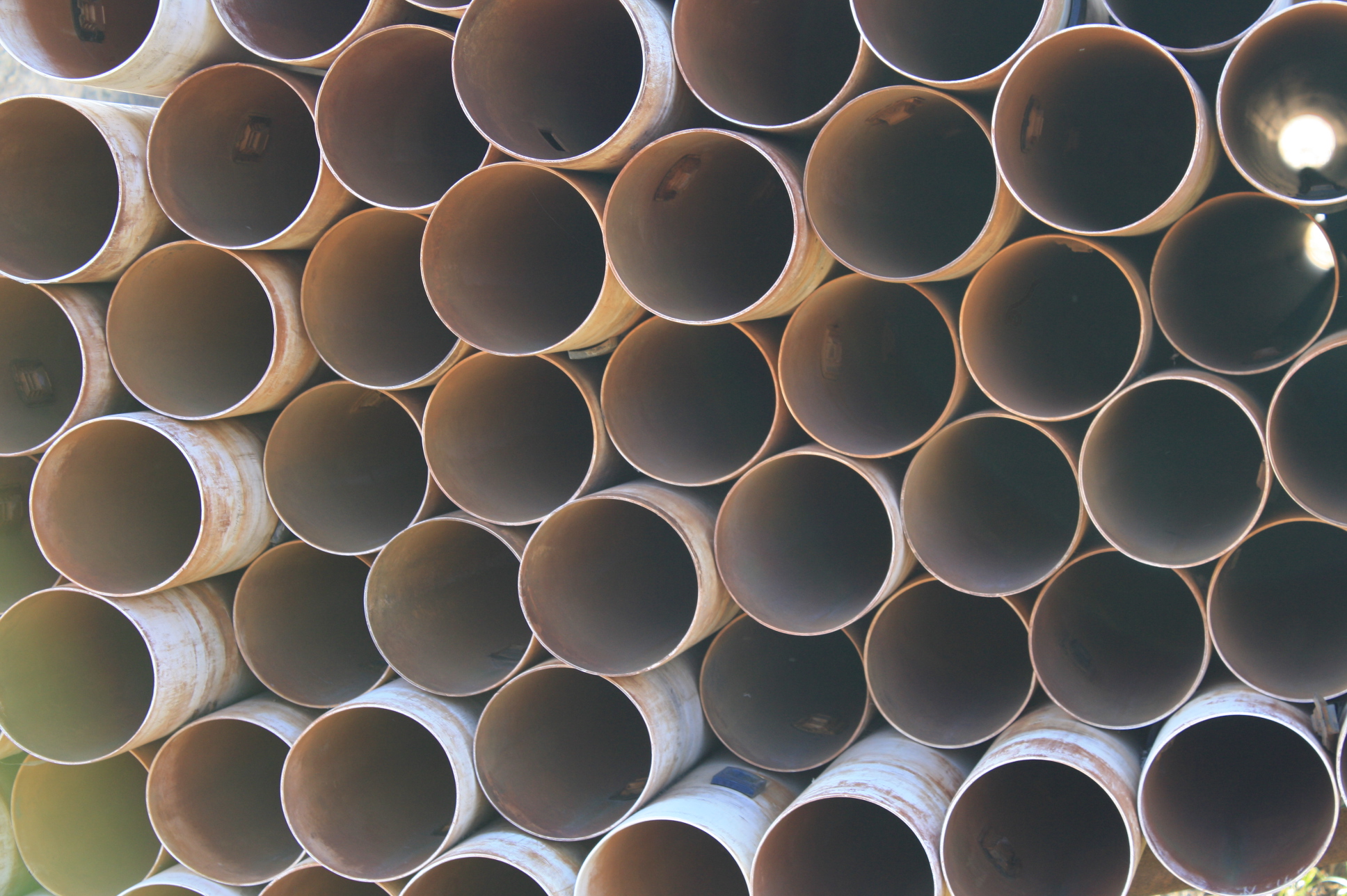

But, when I was a kid, my dad used pipe irrigation. I remember trudging out through the mud and getting the 4-wheeler stuck, just to switch socks on the pipes and flip which row the water was running down. From the time my brother was 8, he dreaded “laying pipe.” Those long metal (and later PVC) pipes had to be placed at the end of the field rows, by hand, and it was a tedious, time-consuming task. Not to mention, the pipes weren’t lightweight!

The invention of the center pivot has impacted agriculture in a positive way by decreasing the amount of hand labor, increasing efficiencies (uniform application of water and inputs), and enabling irrigation to be done on land that had not been able to support crops in the past. It can also be done on all types of terrain, flat or hilly (ever tried to get water to run uphill?).

And, in doing a little research for this story, I came across an obituary for Robert Daugherty, “A Nebraska manufacturer who reshaped the landscape of rural America by pioneering the use of mechanized center-pivot irrigation systems that watered fields in a circular pattern, died Nov. 24, 2010.Mr. Daugherty began his career in the 1940s as part owner of a machine shop that built farm implements in a simple steel shed. By the time he retired as chairman in 1996, his company, now called Valmont Industries, was doing more than $550 million in business a year.”

And you just thought this was a close-up picture quiz.

Until our next history lesson…