Before I buy a shirt, I look at the label to see if it’s 100% cotton. If it is, it usually requires ironing. I think I have an iron and ironing board somewhere in the house. Maybe. 100% cotton means it stays on the rack and I look for another shirt. I bet when Grandpa’s mother made a sweater out of wool, Grandpa didn’t say, “I don’t like to wear 100% wool. It’s scratchy. Can you make a different one?”

Before I buy a shirt, I look at the label to see if it’s 100% cotton. If it is, it usually requires ironing. I think I have an iron and ironing board somewhere in the house. Maybe. 100% cotton means it stays on the rack and I look for another shirt. I bet when Grandpa’s mother made a sweater out of wool, Grandpa didn’t say, “I don’t like to wear 100% wool. It’s scratchy. Can you make a different one?”

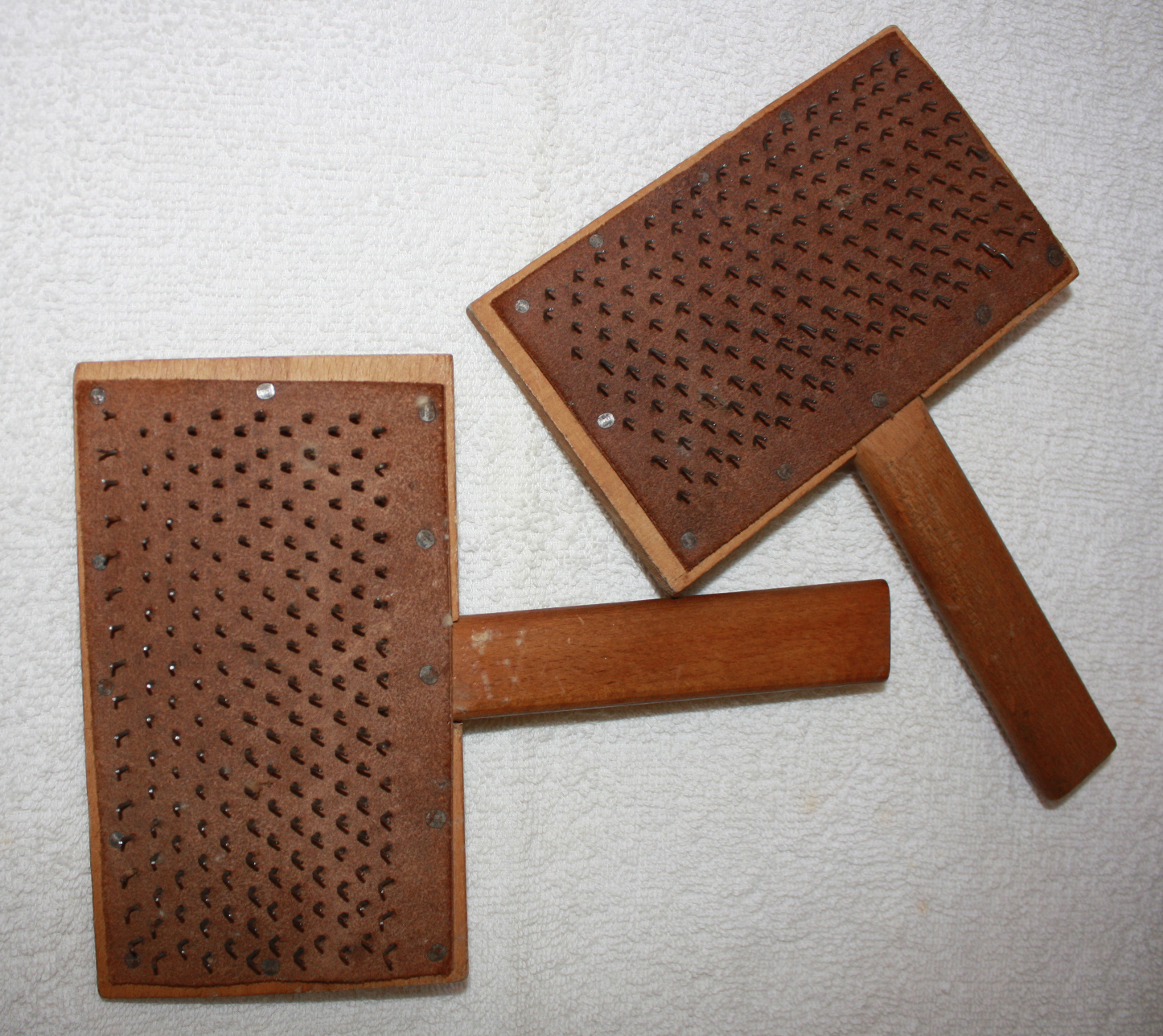

And his mom made the sweaters entirely by hand, starting with carding. A pair of cards (pictured here) is used to brush the wool between them until the fibers are more or less aligned in the same direction. The aligned fiber is then peeled from the card as a rolag and used for spinning, which then in turn, is used to make clothing.

To card, the person carding sits with a card in each hand. The card in the non-dominant hand rests on a leg. A small amount of fiber placed on this card and the other card pulled through the fiber. The moving card separates, straightens, and aligns the fibers. This step, repeated many times, transfers small amounts of the wool to the moving card. Once all the wool has been transferred, the cards are swapped hand-for-hand and the process repeated until all of the fiber is sufficiently aligned and satisfactorily free of debris at which time a rolag is peeled from the card.

They now have drum carders, cottage and commercial carders so people don’t have to do this by hand. I bet Grandpa’s mother would’ve enjoyed the extra free time. To think I don’t even remember how to turn on my sewing machine.

Until our next history lesson…